typical laptop manufacturer drop test shock|drop test standards for electronics : trader It also appears that the test is conducted with the equipment off. While most manufacturers test using Procedure IV (Transit Drop), testing according to other procedures might make more . 7 de jul. de 2023 · No âmbito da engenharia, o termo engenho refere-se à habilidade e capacidade de criar, projetar e construir máquinas, dispositivos e estruturas .

{plog:ftitle_list}

Forge of Empires Forum. New posts General Contains import.

CNET Australia took a tour of Lenovo's ThinkPad testing facility, where notebooks are dropped, chilled, heated, pushed and pulled to their limits.It also appears that the test is conducted with the equipment off. While most manufacturers test using Procedure IV (Transit Drop), testing according to other procedures might make more . We will discuss the various drop test standards that consumer electronics need to pass in order to be considered safe for use by consumers. We will also look at how these tests . Mechanical shock tests are very important for portable electronic products such as notebook computers and mobile phones because these products are subjected to

Enter Dell's Latitude E6400 XFR, the company's next-gen "fully rugged" platform, announced today and engineered to meet the needs of the most demanding customers: the . Did your laptop ever let you down right before that important presentation? Learn here how the Mission Synthesis testing method ensures laptop reliability.

Engineers can use shock response analyses to ensure electronic components meet industry certification standards. Read this blog post to compare 2 methods. Request . Our drop test ensures that those daily jostles don’t add up to long-term damage. Our resident hardware sadists drop each product from a height of 30cm. They repeat the test .

0-32 refractometer

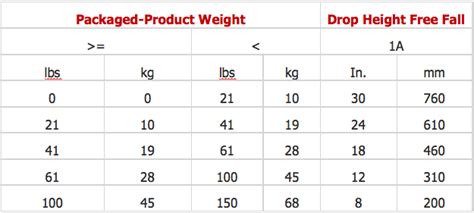

Key steps in a typical drop test include: Package Preparation: The package is prepared with the product inside, following the standard's guidelines. Drop Height: The .A typical spring is shown in the background. The purpose is to isolate the control room from mechanical shock and vibration in the event of a nuclear strike above the launch site. . (PEDs) are expected to survive multiple drops. Most original .The determination of the drop height is crucial as it simulates real-world scenarios of products being dropped during handling or transportation. Product drop test standard height guidelines vary depending on factors such as the .The most commonly referenced method to test a rugged military grade tablet PC is the MIL-STD-810G specifications for shock and vibration or mil spec drop test. . While the most commonly referenced test is the drop test, there may be .

Established in 2000, Linkotest has emerged as a premier manufacturer of reliability testing equipment in China. Our comprehensive range of testing solutions for test labs includes vibration test systems, shock test systems, .A drop tester is a specialized machine used to evaluate the durability of packaging against impacts, shocks, and drops during handling, shipping, and transportation. By lifting and dropping a test specimen from various heights and angles onto a hard surface, it simulates real-world conditions to observe and assess the impacts on different parts of the package.During a free-fall drop shock test, the product is mounted to a test table. The acceleration amplitude and shape of the pulse are determined by two factors: the height from which the product is dropped and the impact surface material. The height determines the overall peak acceleration; the higher it is, the greater the acceleration when the . Our top pick for the best rugged laptop is the Getac S510 for its highly configurable options for shock, drop, moisture, and dust resistance as well as options for multiple storage drives .

Drop/impact protection is an important concern for the design of portable electronic products. Drop/impact forces may cause severe functional damage in form of component failure and/or .

SRS Shock SRS shock testing is commonly used to determine a test article’s ability to tolerate the mechanical stress waves produced by a high frequency, High-G shock event, such as rocket stage separations. SRS shock specs are found in most aerospace hardware test procedures, given as a graph profile showing “response” acceleration

When performing an ASTM D5276 drop test, the impact surface must be: Horizontal and flat Built with concrete, steel, or stone; Durable enough not to deform under test conditions; A rigid mass equal to 50 times or more the mass of the heaviest sample being dropped; Sufficiently large so that the test sample falls entirely on its surfaceIn general, shock acceleration events may easily exceed 5,000 g or more with pulse durations of less than 10 ms (1 g = 9.80665 m/s2). Many test laboratories will shock calibrate each sensor before and after every test to check if the transducer survived and to validate the acquired data.Mechanical shock tests have typical durations of less than one second per shock, although multiple shocks over longer time periods are commonly performed. Mechanical shock testing is also distinguished from thermal shock testing which is performed by very rapidly changing the temperature of the test sample. Typical Mechanical Shock Testing .The AutoShock-II ™ is a fully automated series of shock test systems used to measure and identify product fragility levels and evaluate protective packaging. . manufacturers can systematically test and optimize product design and packaging. L.A.B. Equipment, Inc.’s fully automated computer controlled shock and data analysis test systems .

This is ensured through a robust Quality Management System and Test Method Validation program. The drop test machine(s) should be subjected to an annual preventative maintenance program. The height of the drop should be confirmed with a calibrated ruler, ideally to an accredited reference standard. The impact surface used in testing should .

International product transportation organizations are at the forefront of establishing crucial drop test standards to guarantee the safe and reliable transportation of goods. One such standard is the ASTM D4169 protocol, .Test engineers needed to develop an impact test machine for automotive bumper testing. The bumper was required to absorb approximately 3,000 Joules in a designated crumple zone. Instron engineers modified their model 8150-drop tower shown in Figure 1. It is capable of generating 27.8 kJ of energy from a drop height of 96 in (2.4 m) andDuring shock testing, products are subjected to a series of controlled impacts that vary in intensity and direction. These impacts can be delivered in different ways, such as drop tests or mechanical impacts, depending on the product being tested. Shock testing is used to identify weaknesses in products and to ensure that they meet safety .

It took the B300 only 45 seconds to boot into Windows XP, but its score of 15.7 MBps on the LAPTOP Transfer Test was on the slow side--about 1 MBps slower than the mainstream average. Wireless .

Conducting the Drop Test: A drop testing machine or a free-fall method is used to ensure precise and repeatable drops. The method of dropping (manual or mechanical) should align with the standard being followed. Inspection and Evaluation: After the drop test, the package and product are inspected for any signs of damage. The criteria for . The math may not reflect the actual test parameters. A typical shock test uses a half-sine or sawtooth waveform, which does not correspond to a constant acceleration model. Additionally, such shocks are highly dependent on the material of the part and the surface being hit. Without doing the full analysis, you may understress or overstress the .

iPhone 12 Pro face-down drop test results (Image credit: Allstate Protection Plans). The lower-half of the Ceramic Shield display was cracked, but the 9 smartphone continued to function normally.Transit drop test... 29 TABLE 516.5-VII. Terminal peak sawtooth pulse test parameters (refer to figure 516.5-10)... 29 TABLE 516.5-VIII. . Typical shock time history with envelope, TE and Te. ... 2 FIGURE 516.5B-1b. Typical shock time history .Shock Machine Specifications Overview • Keypad Entry of Test Parameters (with 12 character alphanumeric display) • Shock Testing from 3g’s to 30,000g’s • Test Specimen Weights Up to 1,000 Pounds (453.59 kg) • Shock Durations from 0.012ms to 100ms • Single or multiple drop cycles at a rate of up to 8 cycles per minute

Lansmont Model 23 Shock Test System customized with a Dual Mass Shock Amplifier was used for this testing (Figure 1). Test fixtures were custom designed to mount a circular circuit board consisting of daisy chained electrical devices encapsulated within a 2" housing (Figure 2). Shock forces can be achieved up to 25,000 g with this equipment.

The Latitude 5430 is a semi-rugged laptop with a sleek design that can be outfitted with an 11th Gen Intel Core i5 or i7 processor. Unlike other rugged laptops, which are less subtle due to their .

KING DESIGN was founded in 1983, a world-famous own brand manufacturer of testing equipments in the field of vibration, shock, drop, solar cell and environmental test, which providing total solutions of test and measurement instruments, as well as custom made one-stop systems for various technology industries. With more than 30 years of relative experiences, .

Classical shock testing consists of the following shock impulses: half sine, haversine, sawtooth, and trapezoid. Pyroshock and ballistic shock tests are specialized and are not considered classical shocks. Classical shocks can be performed on Electro Dynamic (ED) Shakers, Free Fall Drop Tower or Pneumatic Shock Machines. The parameters required to .

drop test standards for electronics

webThe latest tweets from @mudryk

typical laptop manufacturer drop test shock|drop test standards for electronics